Then It occurred to me that If I could get the Mito to brake much harder, turn fast, accelerate more rapidly and hit a higher top speed that I could run with the big-boys in the fast group even with my novice skills So I had the motivation, all I needed was an excuse;

30minutes later while running a hot lap, I went around the outside of an 1198S at turn two, lent her over too far, dug the foot peg into the track and top a trip into the gravel at 150. ouch

Sounds to me like an excuse for a project. It had to be a 2T, The powerband is like a drug. So I decided to build a 2T supermono.

The aim of the bike was to build a bike for less than a 5 year old 600cc bike ($7000)

The bike needs to be able to round up a stock 600 on a big track like phillip island and I wanted to give a 1000cc bike a run for its money on a tighter track like Broadford. 2 weeks later when I could walk without looking like Id crapped my pants I started making phone calls and found a bloke in Newcastle who knew his 2Ts, he was referred to me by Steve from Two Stroke Shop.

So far during my daily ebay searches Iv found the following bits, at very cheap prices to keep the bike within budget.

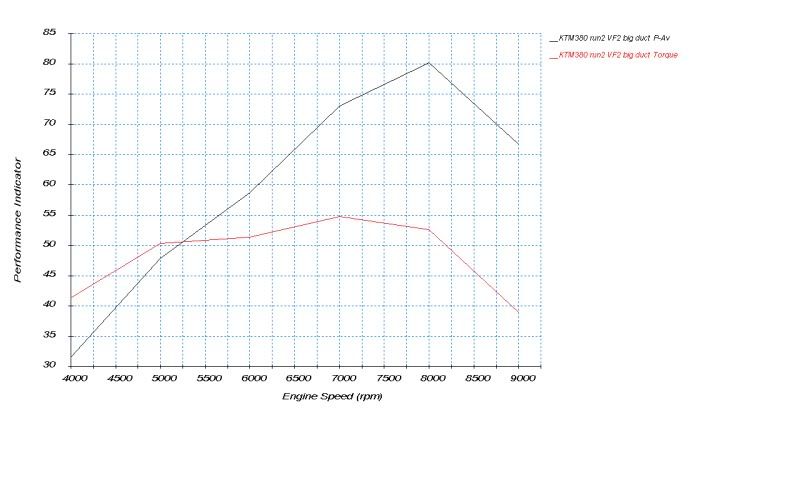

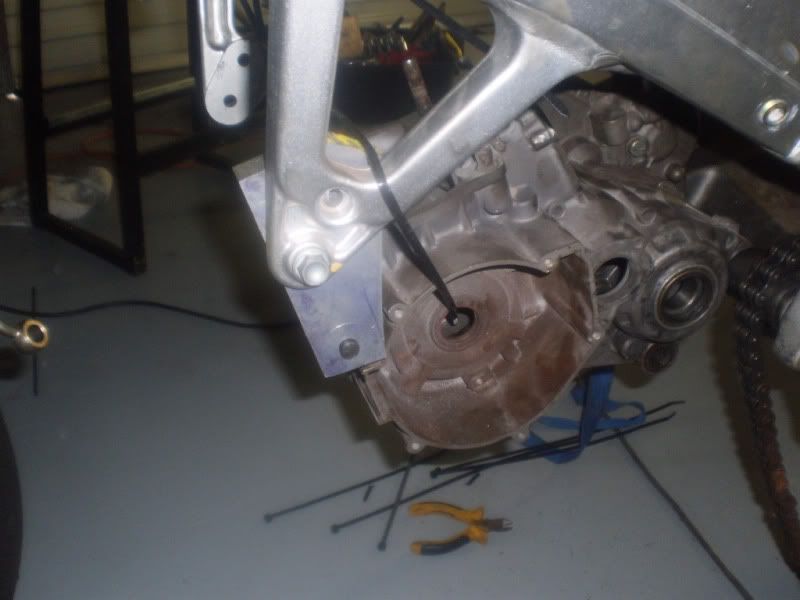

KTM380 motor with an Electronic Power Valve (EPV) similar to that used on a late model 2Ts<BR>Motor has a Wiseco Piston,

custom shaped head,

cleaned up ports,

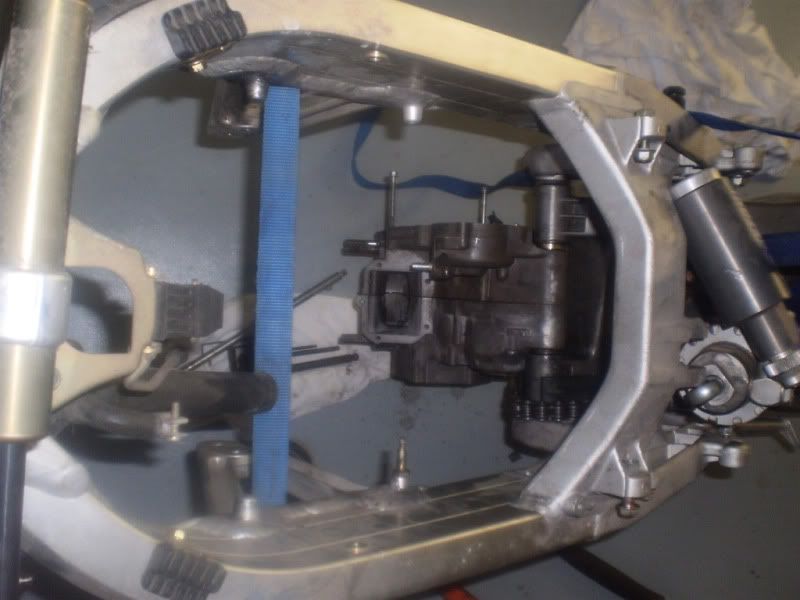

39mm PWM eliptical slide, shortened carb' with solendoid controlled power jets

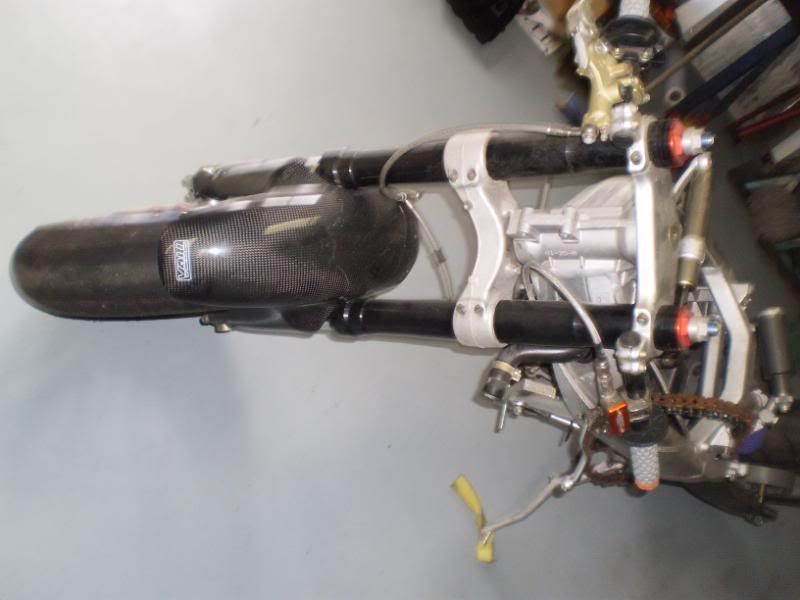

Custom Two Stroke Institute Pipes,

and reworked exhaust ducts to mimic the last generation Aprilia 250 GP bikes

Ignitech ignition

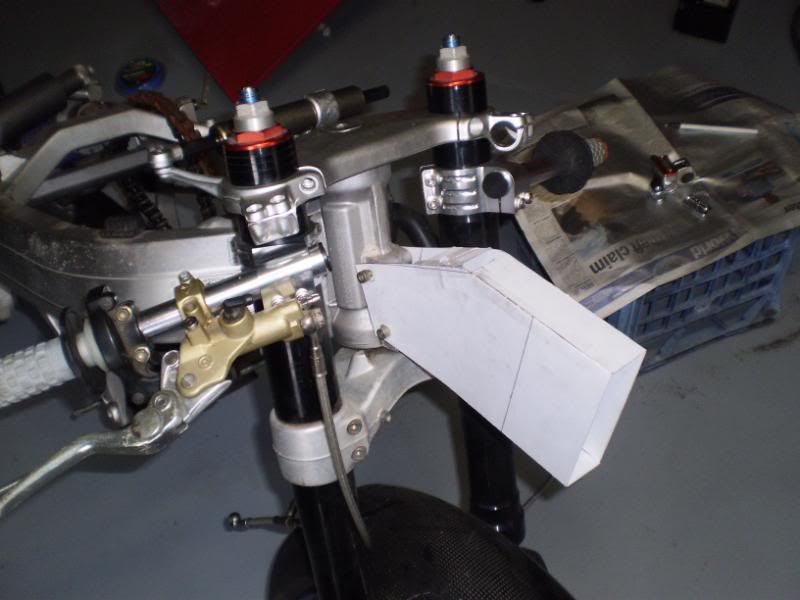

Aprilia RS250 adjustable Showa Forks

Honda RS125 Maxton TT shock

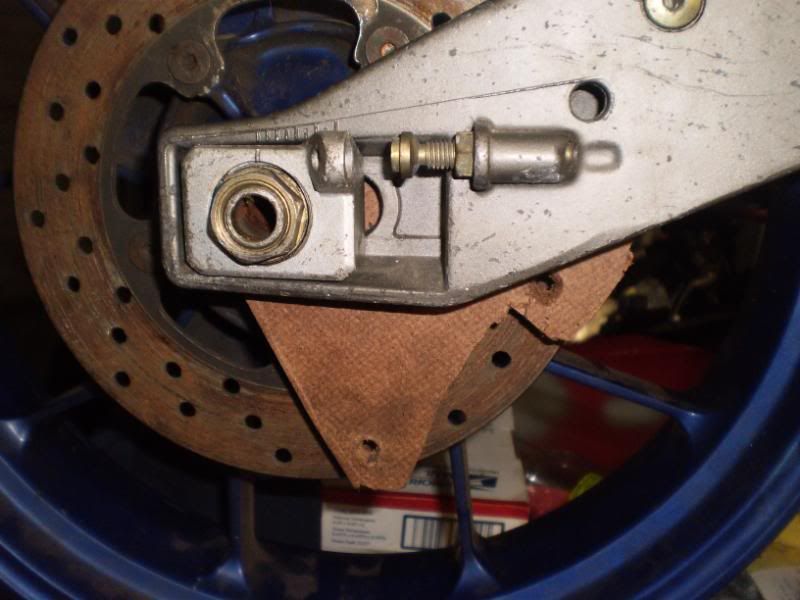

Aprilia yspoke wheels

Aftermarket gasket and seals

525 pista race glass from Netherlands

Race discs from EBC

Talon Custom Sprokets

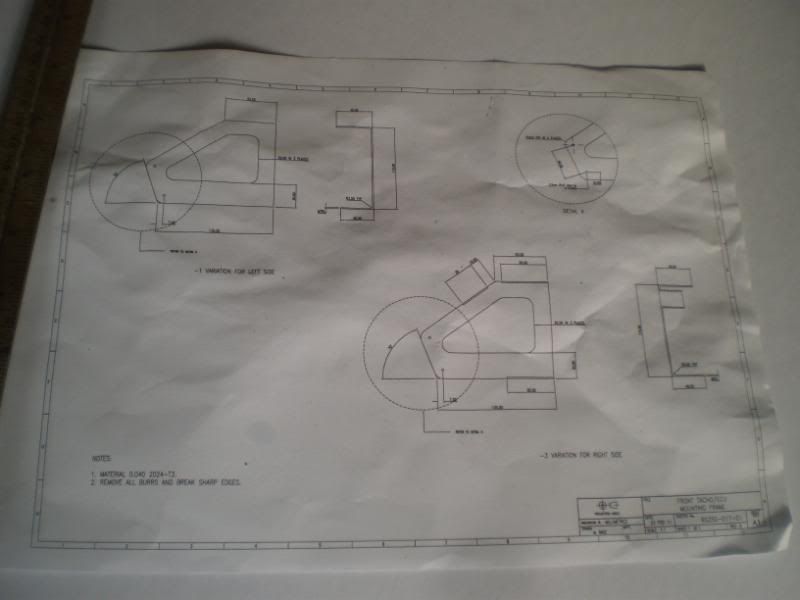

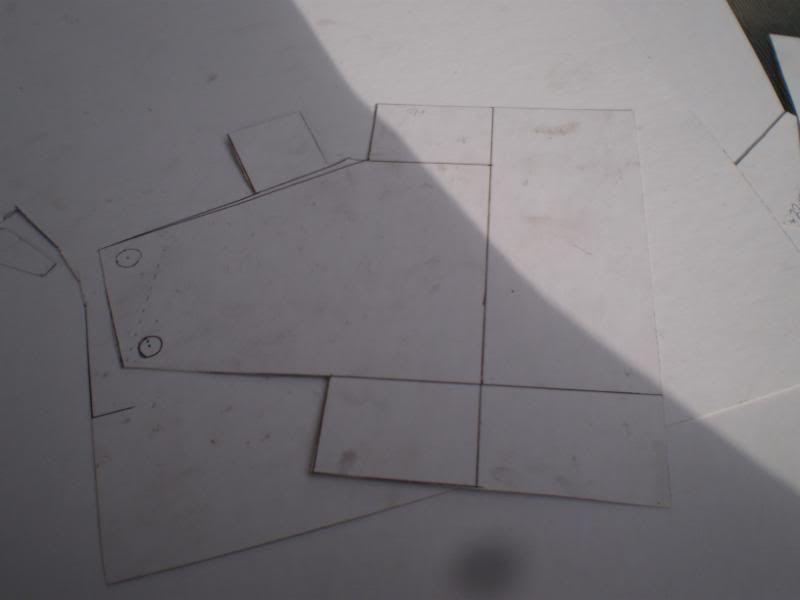

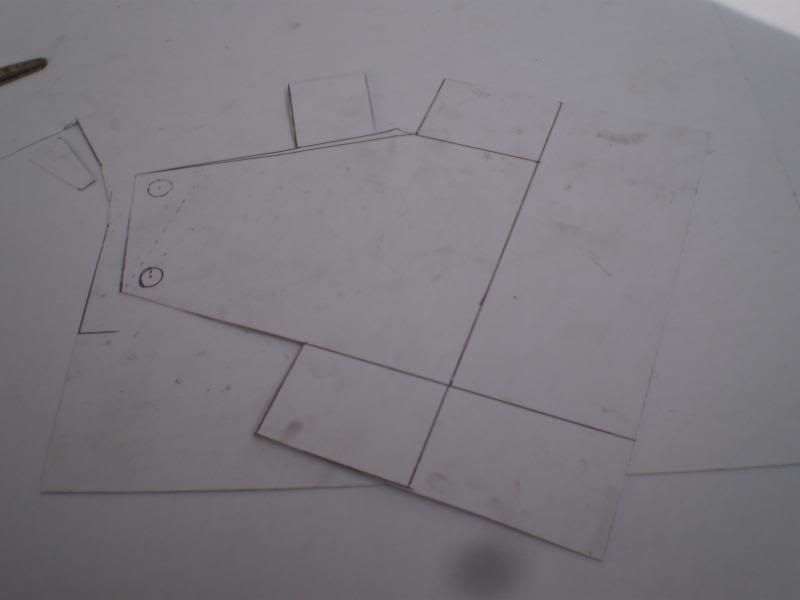

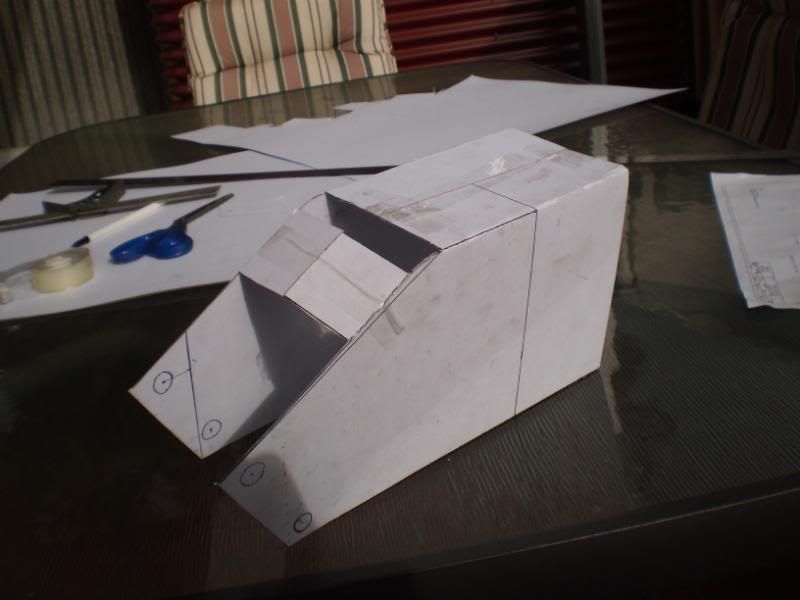

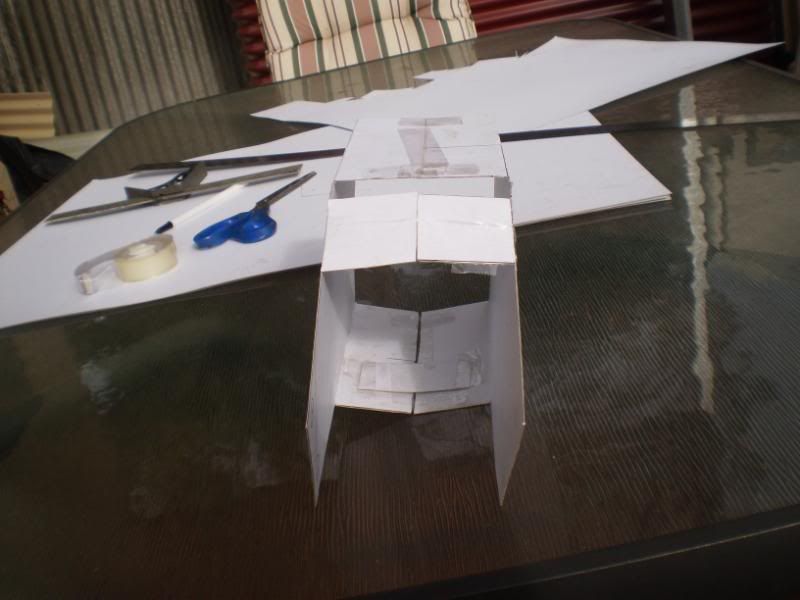

Custom Subframe (front and rear

RGV vj22 race tail

Dunlop KR slicks,

125/55 or 120/70 front,

155/60 rear Pirelli dragon

Also picked up an r6 radiator and goodridge clutch lines this week.

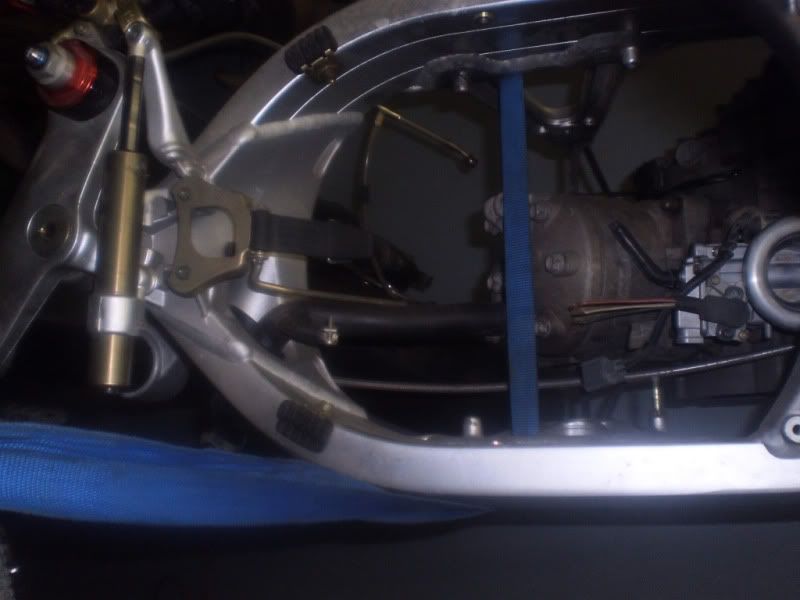

Here are some pics of the motor in the frame

http://i70.photobucket.com/albums/i92/Sabo...reet/jeram2.jpg

http://i70.photobucket.com/albums/i92/Sabo...reet/jeram2.jpg

Expected final outcome

MORE COMMING IN 5 MINS